Introduction: Why the Right Grip is Your Best Safety Investment

Hand injuries send over one million workers to the emergency room annually, and shockingly, 30% of those injured were wearing inadequate gloves for the task.

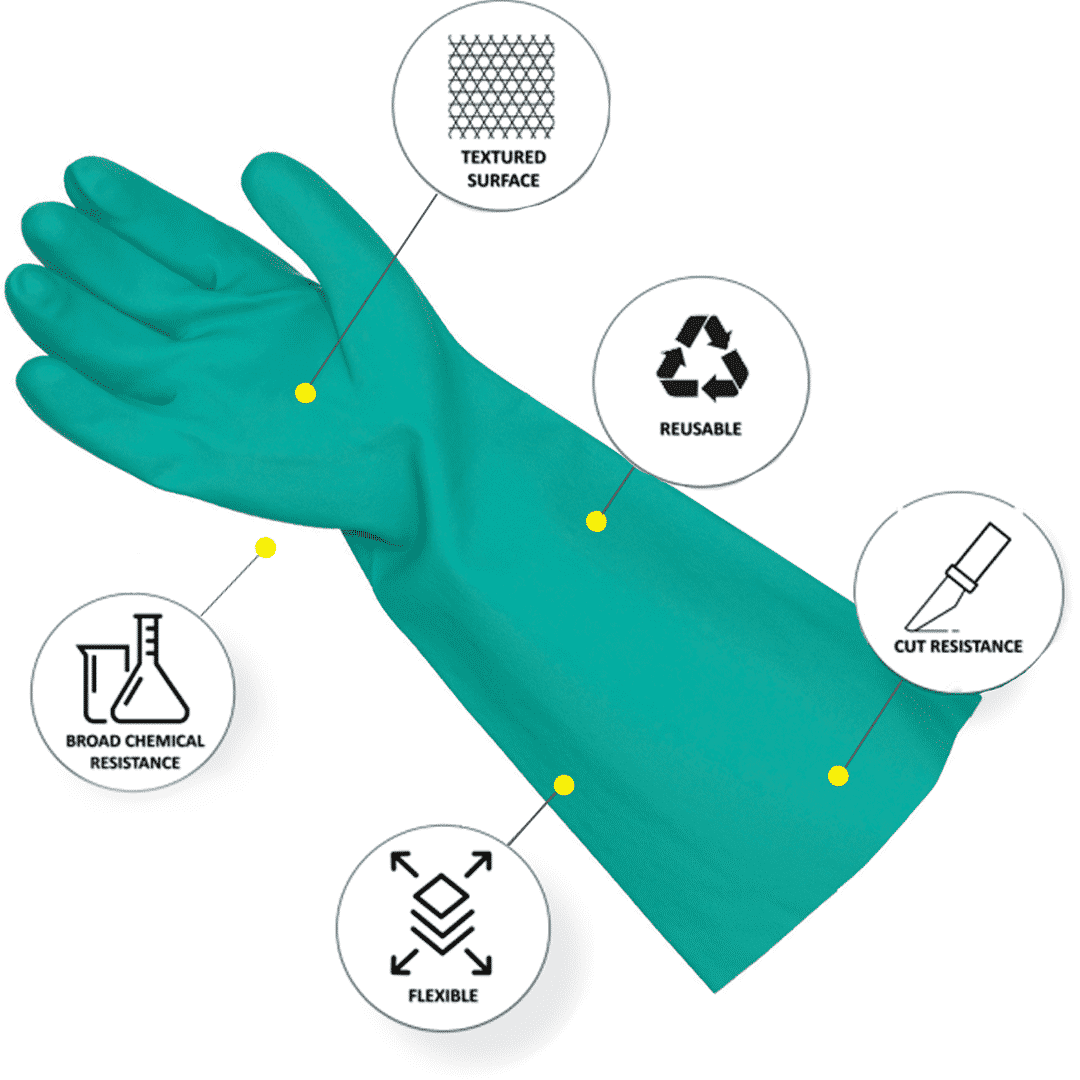

In industrial environments, the glove surface texture and grip technology are the critical features that determine performance and safety. For reusable gloves (those typically 14-mil thick or greater ), bulk material provides necessary chemical protection, but it sacrifices tactile sensitivity. Specialized surface finishes are not enhancements—they are essential engineering solutions required to restore control and mitigate slippage, especially in contaminated environments.

Choosing the right finish—whether diamond-pattern, micro-rough, or sandy—is a high-return safety measure. By reducing slip incidents and fumbling time, organizations can see significant savings, as each workers’ compensation claim for lost time approaches an average cost of $7,500.

1. The Science of Grip: How Texture Beats Liquids

The fundamental challenge to grip is a continuous layer of liquid (oil or water) that forms between the glove and the object, causing hydroplaning. Engineered finishes are designed to actively manage this liquid interface to maximize the Coefficient of Friction (COF).

Three Engineered Finishes and Their Mechanisms

| Finish Type | Best For | How the Texture Works (The Science) | Base Materials |

| Micro-Foam / Micro-Rough | Wet, Damp, or Light Oil Conditions | The microporous structure acts like a sponge or thousands of “tiny suction cups” to absorb and displace fluids away from the contact point, ensuring a consistent polymer-to-object contact.4 | Nitrile, Latex |

| Diamond / Raised Pattern | Heavy Grease, Bulk Oil, Sludge | This macro-scale geometric pattern acts like “deep tyre tread,” creating deep channels that physically evacuate high volumes of viscous liquids from the grip zone under pressure.7 | Heavy-Duty Nitrile, PVC |

| Sandy / Crinkle | Dry, Slippery (Non-Oily), Abrasion Risk | Creates a high density of small bumps and ridges on the surface, maximizing the number of physical contact points for superior friction and a mechanical, “suction-like grip”.9 | Nitrile, Latex |

| Smooth | Precision, Inspection, Double-Donning | Provides maximum tactile sensitivity but offers minimal grip in wet or oily conditions, as the slick surface actively repels liquids.11 | Nitrile, Latex |

2. Match the Right Texture to Your Task

The specific contaminant and task dictate the required texture. Pairing the correct base material (Nitrile for oil resistance, Neoprene for certain acids, etc.) with the optimal texture is non-negotiable for safety.

| Application | Primary Contaminant | Recommended Texture & Material |

| Automotive / Heavy Maintenance | Heavy oils, grease, solvents | Diamond-Pattern Nitrile.14 The raised pattern manages high-volume viscous liquids. |

| Wet Food Prep / Janitorial | Water, cleaning chemicals, non-viscous liquids | Micro-Foam Nitrile or Crinkle Latex.15 Foam absorbs and displaces dampness for secure wet grip. |

| Assembly / Electronics Inspection | Dry parts, fine motor tasks | Smooth Nitrile with Micro-Textured Fingertips.17 Prioritizes tactile sensitivity and dexterity. |

| General Warehousing / Logistics | Boxes, dry surfaces, moderate abrasion | Sandy Grip Nitrile or Rough-Coated PVC.10 Maximizes friction and provides high abrasion resistance. |

3. Performance Metrics: How to Validate Grip and Durability

Claims of superior grip must be backed by objective data. When evaluating reusable gloves, ask suppliers for test results related to these core metrics:

- Coefficient of Friction (COF): This is the fundamental measure of slip resistance. Testing performed using standards like ASTM D1894 measures the static and kinetic force required for the glove to slide across a surface. A high COF value indicates that the engineered texture is effectively reducing slippage, which in turn reduces the need for the operator to over-grip, decreasing hand fatigue.

- Abrasion Resistance (EN 388): Because texture provides the grip, the texture must be durable. The EN 388 standard’s Abrasion Resistance rating (Level 1-4) confirms how many cycles of friction the glove material—including the texture—can withstand before failure. A high rating ensures the grip mechanism will last for the extended life of the reusable glove.

- Grip Retention After Exposure: For chemical tasks, the glove must maintain its physical properties after exposure. Manufacturers test this by confirming that the glove material’s tensile strength and physical dimensions remain within safety thresholds after being immersed in target chemicals or oils (e.g., 72-hour immersion tests).

4. Maximizing the ROI of Your Reusable Gloves

The economic argument for using the right texture is simple: superior grip increases safety and throughput. Safety managers have seen improved worker productivity and significant savings by implementing extended-use gloves with improved grip.

To maximize the Total Cost of Ownership (TCO) of your reusable, textured inventory, two factors are key:

A. The Criticality of Fit

The full benefit of an advanced texture is achieved only when the glove is correctly sized. A properly fitted glove maximizes the pressure applied through the textured surface, ensuring the liquid displacement mechanism works as designed. Poor fit reduces control and can functionally negate the grip advantage.

B. Cleaning Protocols for Texture Retention

The engineered grip texture can degrade from mechanical abrasion during use, but improper cleaning protocols also pose a major risk to the glove’s lifespan. To preserve the structural integrity of the texture (whether it’s foam pores or diamond ridges):

- Use Cold Water and Mild Soap: Reusable nitrile or coated gloves should be washed in cold water with a pH-neutral, mild detergent. Warm water risks shrinking the polymer and distorting the texture’s shape.3

- Avoid Harsh Chemicals: Oxidizing agents and bleach can chemically degrade the coating, causing discoloration and compromising the coating’s intended grip performance.

- Air Dry: Always air-dry the gloves to prevent shrinkage or deformation of the engineered surface that can occur with heated machine drying.

FAQ: Grip and Durability

Q: Does glove texture wear off?

A: Yes. The surface roughness that creates the grip wears down due to constant friction and abrasion.33 This functional degradation can occur long before the glove tears. The useful service life of a textured glove should be based on estimated hours of use with abrasive materials, not just visible signs of structural failure, to ensure the COF remains safe for the job.

Q: Are textured gloves harder to use for precision work?

A: Very thick or heavily textured gloves (like a Diamond pattern) can reduce fine motor control.34 However, newer micro-foam and micro-textured coatings are specifically engineered to provide enhanced grip while maintaining high levels of dexterity and tactile sensitivity, making them suitable for assembly and service work.

Q: Should we color-code our gloves by texture?

A: Yes. Implementing a color-coding system (e.g., Green for Smooth Inspection, Red for Diamond Heavy-Duty) is a best practice for rapid selection, clear communication, and ensuring operators use the right grip for the specific hazard or environment, minimizing risk of the “wrong glove for the job”.

Conclusion & Next Steps

The proper surface finish on a reusable glove is the tactical component that converts general hand protection into verifiable job-specific safety. By understanding the hydrodynamic science behind each texture and validating performance with COF and abrasion metrics, organizations can proactively eliminate slip hazards, reduce operational downtime, and ensure maximum productivity from every team member.