Introduction: Moving Beyond Marketing Claims

A clear glove field trial separates marketing claims from real-world performance. While lab data provides a baseline, it often misses the specific handling patterns and mechanical stresses unique to your environment “. This playbook walks procurement and safety teams through selecting test SKUs, designing measurement forms, and calculating the true Cost-Per-Use (CPU)—empowering you to choose the right latex, nitrile, or PVC glove with absolute confidence.

1. Why Run a Glove Field Trial? (The Business Case)

Relying solely on a vendor’s technical sheet can lead to expensive “bad buys.” A structured pilot program provides:

- Real-Use Validation: Pilots reveal failure modes—such as seam tears or chemical breakthrough—that standard lab tests on new, un-stressed gloves might not catch “.

- True ROI Decisions: By measuring how many uses a glove actually survives, you move from “cheapest per box” to “most cost-effective per shift” “.

- Worker Acceptance: Engaging staff in the decision-making process increases PPE compliance. Workers are more likely to wear gloves they have tested for comfort and dexterity “.

2. Pilot Design: Selecting SKUs, Teams, and Timelines

A successful trial requires a controlled environment to ensure the data is actionable.

- Choose Candidate SKUs: Select 3 candidates per role (e.g., a heavy-duty nitrile, a neoprene-latex blend, and a PVC utility glove). Always include your current SKU as the baseline for comparison “.

- Identify Test Groups: Assign 5–10 operators per SKU. Ensure they work the same shifts and perform similar tasks to keep variables consistent “.

- Timeline: A 2–4 week period is usually sufficient to reveal durability trends and material degradation “.

- Success Metrics: Define clear KPIs before starting: failure rate (per 100 uses), average “time-in-use” before failure, and a worker comfort score (1–5 scale) “.

3. Measurement & Logging: Field Form Essentials

Data is only as good as the log used to capture it. Your field form (digital or paper) should include:

- Failure Modes: Specifically track if the glove failed via a tear, puncture, seam split, or chemical breakthrough “.

- Tactile Feedback: Note any loss of grip or dexterity over time, especially as gloves are cleaned and reused “.

- Template Tip: Use a spreadsheet with three tabs: Daily Logs, Failure Summary, and a Cost-Per-Use Calculator. (Branded templates can be generated using /mnt/data/logo.png for professional reporting).

4. Lab Checks to Run in Parallel

While the field trial runs, perform “bench tests” on the same production batch to verify batch-specific quality:

- Air/Water Leak Test: Use ASTM D5151 standards (filling the glove with 1,000mL of water) to check for pinholes “.

- Tensile & Elongation: Measure the force required to break the material to ensure it meets the manufacturer’s ASTM D412 claims “.

- Abrasion & Friction: For reusable gloves, check the EN 388 abrasion rating (1–4 scale) to see if it survives the expected 2,000 to 8,000 cycles.

- Chemical Spot Test: Drip-test the actual solvents or degreasers used on-site to observe immediate material swelling or shrinkage “.

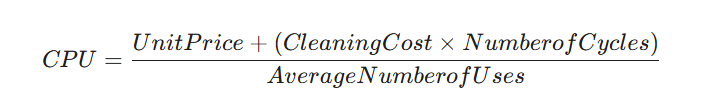

5. Cost-Per-Use (CPU) Calculation

For reusable gloves, the unit price is only a fraction of the cost. Use this formula to find the real impact:

Factors to Include:

- Unit Price: The ex-factory or landed cost.

- Maintenance: For reusables, calculate labor (minutes spent cleaning $\times$ hourly rate) and laundry consumables “.

- Productivity Impact: Factor in the “hidden cost” of rips—every time a worker stops to change a torn glove, it costs approximately 5–10 minutes of production time “.

6. Decision Rules and Scaling the Winner

Avoid “analysis paralysis” by setting pass/fail rules before the data comes in:

- Safety Threshold: The SKU must maintain an Acceptable Quality Level (AQL) for leaks (typically 1.5 for medical/high-risk tasks) “.

- Durability Rule: Max failure rate should be $<2\%$ per 100 uses in standard cleaning environments.

- Scaling: If a SKU passes, scale the pilot to 20–50 users for a final “stress test” before full facility rollout “.

7. Example Timeline & Responsibilities (2-Week Plan)

- Day 0: Kickoff meeting; train staff on logging; issue color-coded sample packs.

- Day 1–7: Active field use; team leads collect daily logs; midweek “check-in” for immediate safety issues.

- Day 8: Conduct air/water leak tests and lab checks on samples from the same batch “.

- Day 9–14: Focus on “failure hot spots” (e.g., do gloves always tear at the thumb during specific tasks?).

- Day 15: Synthesize CPU, failure data, and comfort scores. Decide: Scale, Re-test, or Reject.

FAQ

Q: How many operators are needed for statistical confidence?

A: For most industrial or household procurement, 5–10 operators provide an actionable signal. For high-volume facilities (3,000+ employees), scale to 30–50 operators “.

Q: What if failures are caused by improper “doffing” (removal)?

A: Pair your trial with a quick training session on proper removal—peeling from the cuff to avoid tearing the fingers or contaminating skin “.

Closing + CTA

Stop guessing and start measuring. A structured pilot ensures you don’t just buy a glove, but invest in a proven safety solution.