Introduction: The Strategic “Holiday Lull” (Q1 Glove Procurement)

For procurement and safety teams, the end-of-year holiday period is more than a break—it is a critical window to audit 2025 performance and “stress-test” the 2026 supply chain. With Chinese New Year 2026 beginning on February 17, factories in Asia often halt production 2–4 weeks prior, creating a logistical vacuum that can last until mid-March “.

Use this time to implement five high-impact upgrades to your glove program. By moving from disposable commodities to high-durability, ISO-certified and SGS-tested reusable gloves, you can mitigate lead-time risks, reduce waste, and significantly lower your Total Cost of Ownership (TCO).

1. Upgrade 1: Color-Coding & Cross-Contamination Control

A visual hygiene system is the fastest way to improve safety compliance. Pilot a color-coding rollout in high-risk zones (e.g., food prep or chemical handling) and expand to the rest of the facility.

- Standardize the Map: Use Green for food/produce, Red for high-risk sanitary areas, and Blue for general cleaning.

- Signage: Install high-visibility dispenser headers. Clear identification is proven to be the most effective method for restricting equipment to designated areas.

- The Reusable Benefit: Unlike disposables, color-coded reusable gloves provide a 100% liquid-proof barrier that doesn’t “wick” contaminants, as they lack a fabric liner “.

2. Upgrade 2: Structured Field Trials for Material Performance

Stop purchasing based on box price and start purchasing based on “time-in-use.” Run 2–4 week pilots with 5–10 users per role to validate performance “.

- Failure Logging: Have workers log failure types: Was it a puncture, a seam split, or material “reversion” (stickiness) “?

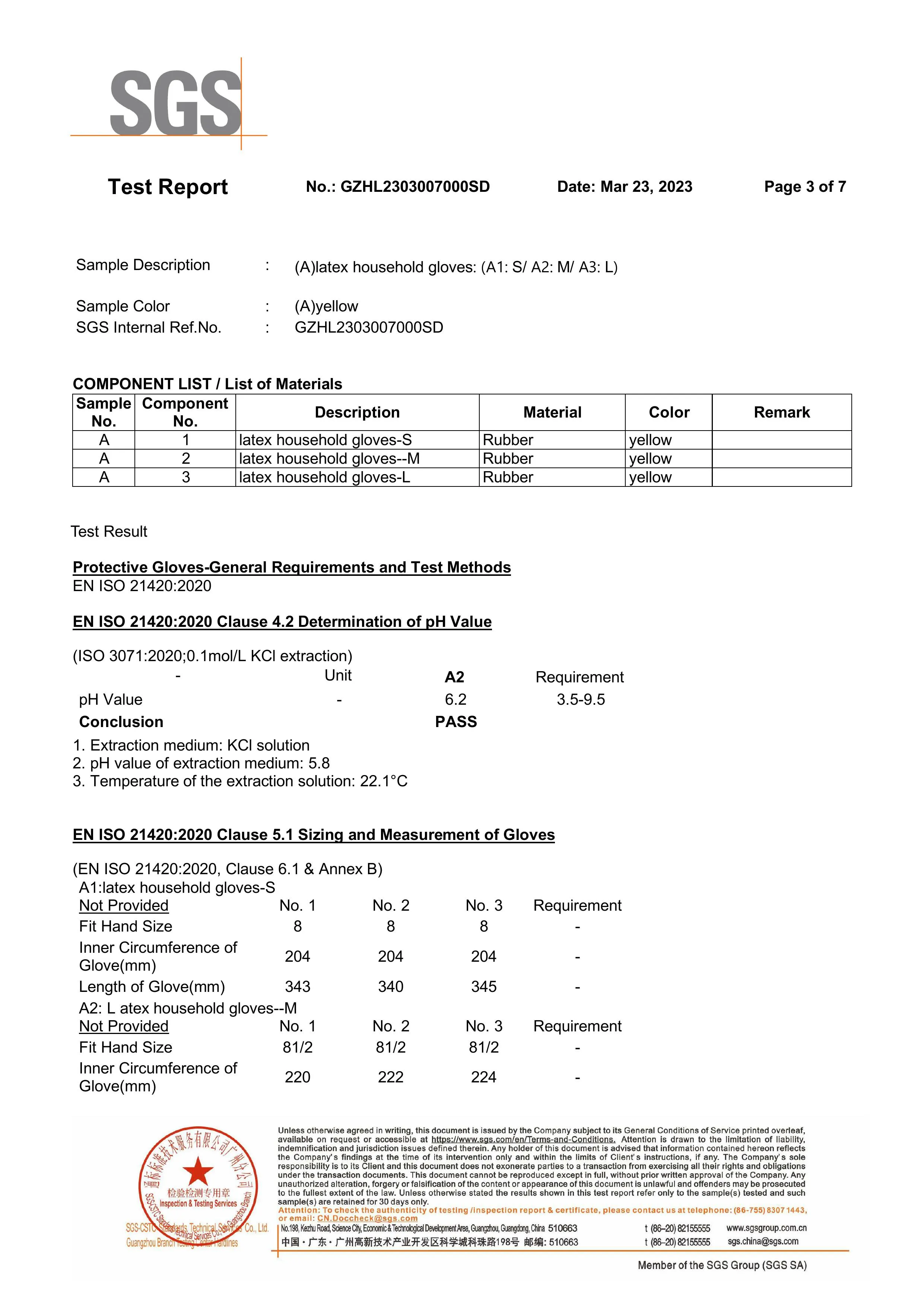

- Lab Pairing: Validate field data with SGS test reports on the same production batch. Check tensile strength (ASTM D412) and leak resistance (ASTM D5151) to ensure the product meets your safety threshold “.

3. Upgrade 3: SKU Rationalization & Inventory Buffer

A bloated SKU list increases storage costs and procurement complexity. Use year-end data to retire low-performing items.

- Simplify Materials: Consolidate your program around 3–4 core high-performance materials like Nitrile for chemical resistance and Latex for high dexterity “.

- The 2026 Buffer: Because factory recovery from the Lunar New Year can take up to six weeks, maintain a 15–30% safety stock for high-velocity SKUs through March “.

4. Upgrade 4: Piloting Features for Comfort (Flocking & Texture)

For unsupported gloves, comfort and grip are the primary drivers of compliance.

- Cotton Flocking: Test internal flocking for workers on long shifts. The milled cotton fibers absorb sweat, reducing the “clammy” feel that causes workers to remove gloves prematurely “.

- Embossed Textures: For wet or oily lines, upgrade from smooth surfaces to Diamond or Fish-Scale molded textures. These increase the Coefficient of Friction (COF), preventing accidents and hand strain “.

5. Upgrade 5: KPI & Cost-Per-Use (CPU) Tracking

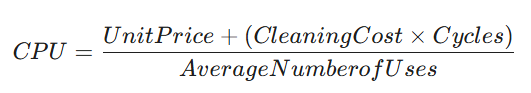

Shift your procurement SLA (Service Level Agreement) from “unit price” to “performance metrics.” Use this formula to track your true savings “:

- Track Monthly KPIs: Measure failures per 1,000 uses and “incident days avoided.” Comfortable, high-durability gloves can reduce “premature changes” by up to 20% “.

- Compliance Verification: Ensure all SKUs are FDA-compliant (21 CFR 177.2600) for food safety and manufactured under ISO 9001/13485 quality systems to guarantee batch-to-batch consistency “.

FAQ

Q: How early should I place Q1 orders to avoid CNY risks?

A: Ideally, secure your Q1 delivery capacity by mid-December. Most Asian factories stop accepting new orders 6–8 weeks before the Lunar New Year holiday “.

Q: Can these upgrades really show ROI in a single quarter?

A: Yes. High-abrasion rated reusable gloves (ANSI Level 6 or EN 388 Level 4) often pay for themselves within 2–6 months by reducing the sheer volume of disposable waste and replacement frequency.

Conclusion: A Proactive 2026 Start

January is the time for action, not reaction. By implementing a color-coded system, auditing performance via field trials, and securing your supply chain against lead-time risks, you position your organization for a safer and more profitable year.

Ready to optimize your 2026 glove program?

Consult with our experts on mixed-pallet quotes and SGS-verified high-durability options.