Intro

Successful holiday glove procurement depends on accurate forecasts and clear MOQs. Use this guide to plan private label options, confirm lead time for custom gloves, and secure packaging mockups so supermarket and e-commerce buyers avoid stockouts during Black Friday and year-end promotions.

1 — Forecasting & MOQ planning for holiday glove procurement

Forecast SKU-level demand using last-year sales + growth factor; add 20–30% safety. Ask supplier about flexible MOQs and options for mixed-color pallets to reduce deadstock risk.

2 — Lead times & production schedule for private-label gloves

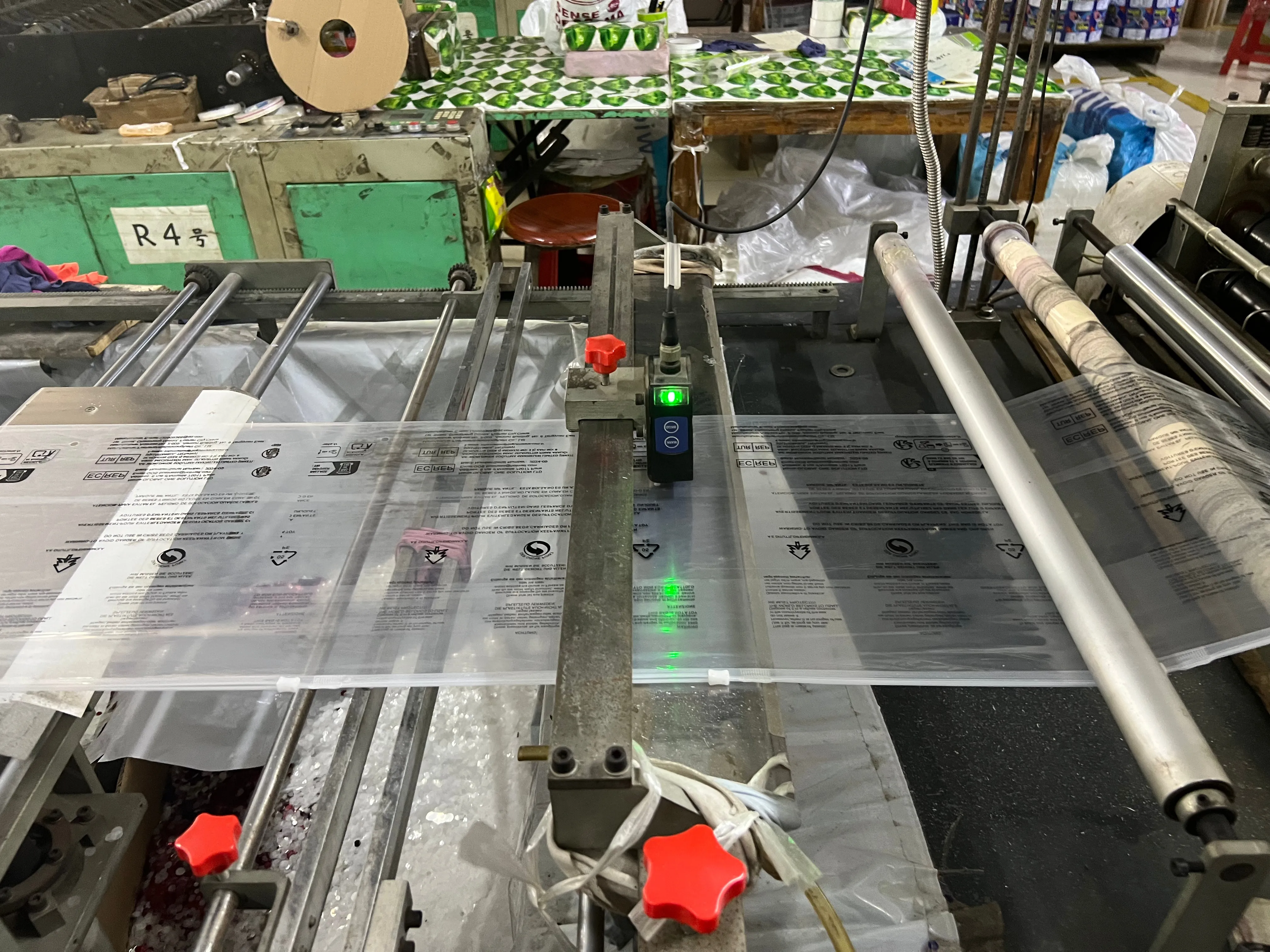

Confirm production lead time (preparation of printing plates, polybag printing, and packing can add 2–3 weeks). For many factories, first-time orders may need 45 days; repeat orders 30–50 days depending on qty and customization—plan accordingly.

3 — Packaging mockups, dielines and retail presentation

- Options: hang-card retail packs, display-ready inner boxes (e.g., 100 pairs), or e-commerce blister packs. Request dielines and pre-production mockups.

- Consider seasonal co-packs (gloves + sponge or cleaning cloth) to increase basket value.

- Require pre-shipment samples and pre-production photos. Confirm labeling requirements for each region (language, batch number, manufacturer info).

4 — Promotional allocations & reserve stock strategies

Secure a promo allocation: hold a small reserve for flash sales. Negotiate partial shipments to spread arrival over promo weeks.

Define non-returnable rules for hygiene SKUs; allow for size exchange or credit in special packaging.

Field tests & merchandising

Run small store pilot with display packs and track conversion rates.

Use planogram suggestions and staff demo packs. Use barcode-friendly packaging for POS and quick reordering.

Closing + CTA

Retail holidays are won by planning. Guangzhou Red Sunshine offers private-label packaging, seasonal SKU suggestions, and flexible MOQ options for promotional runs.