Intro

In industry, glove choice affects safety, compliance, and productivity. This guide helps purchasing managers and safety officers compare **latex, nitrile, and PVC gloves** across chemical resistance, grip, abrasion resistance, and cost-per-use—so you can lower risk without overspending.

Section 1 — KPI framework for selecting gloves

Consider these when choosing industrial gloves:

- Protection requirement: chemicals, oils, cuts, heat?

- Dexterity needed: assembly vs. heavy handling.

- Wear time & reusability: single-shift disposable vs. reusable multi-shift.

- Cost-per-use & total cost: not just unit price.

- Compliance & certifications: CE, EN388, ANSI cut ratings if applicable.

Section 2 — Material performance matrix

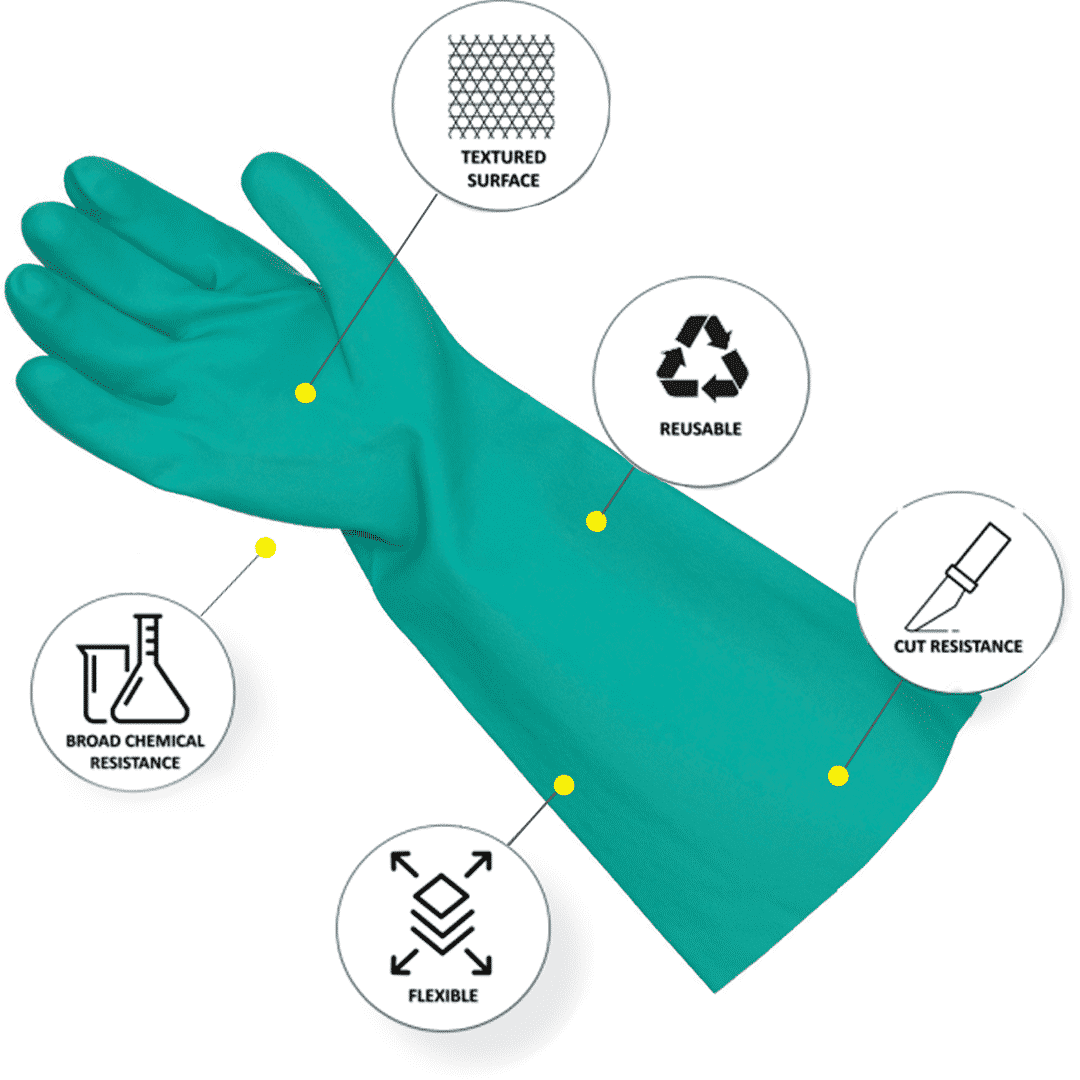

Nitrile (industrial grade)

- Strengths: Chemical & solvent resistance, puncture resistance, excellent for oil/grease environments.

- Typical uses: Automotive, maintenance, oil & gas, chemical handling.

- Recommend: Powder-free nitrile, textured grip, 4–7 mil thickness for disposables; 0.35–0.7 mm for reusable.

Latex (industrial-grade coated)

- Strengths: Outstanding fit & tactile sensitivity, good for assembly tasks requiring dexterity.

- Typical uses: Electronics assembly, light manufacturing, inspection tasks.

- Recommend: Be mindful of allergy-safe alternatives for workforce.

PVC (coated or dipped work gloves)

- Strengths: Resistant to oils and some solvents, economical for heavy wet handling, long-lasting dipped varieties.

- Typical uses: Shipyards, food processing, wet manufacturing lines.

- Recommend: Use PVC-dipped canvas or knit shells for abrasion and comfort.

Section 3 — Practical procurement strategies

- Segmentation: Buy multiple SKUs per facility—don’t force one glove to do all jobs.

- Field trials: Run a 2–4 week pilot in one line; collect feedback on dexterity, comfort, failures.

- Track failure modes: Punctures, seam failures, chemical breakthrough—feed data into next purchase.

- Bulk & packaging: Offer inner-pack sizes and dispenser-ready cartons to reduce waste on the floor.

Section 4 — Cost-per-use example

Calculate: (Unit price × units used per month) / protective life (days) = real cost per workday.

* Often, premium reusable gloves have lower cost-per-use than cheap disposables.

Section 5 — Compliance & labeling checklist

- Ask suppliers for material safety data, EN/ANSI ratings, and chemical breakthrough time charts.

- Require traceability info for large tenders.

Case study

A warehouse cut glove-related incidents by 40% after switching to nitrile with cut-resistant liners on packing lines—reduced downtime and returns in 3 months.

Closing + CTA

Need a tailored glove audit or product samples for your workforce? Guangzhou Red Sunshine Co., Ltd. offers free site-assessment checklists and bulk sample packs for industrial buyers.

GET IN TOUCH